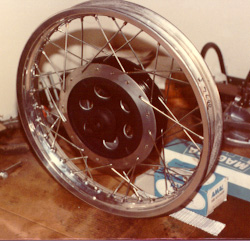

| 4) Wheel Service 4) Front. A) Place machine on cycle stand, raise front wheel. B) Cut-off and remove all safety wire. C) Undo front axle nut. D) Undo lower-right fork pinch bolt, do not remove. E) Remove front brake cable at either end. F) Remove axle then front wheel. If DLS-Honda wheel fitted, undo/remove brake anchor bolt. G) Check condition of brake shoes and related parts, replace or service as needed. H) Check condition of wheel bearings, replace as needed. To replace, place suitable drift into wheel, move spacer to one side. Warm bearing area, then drift out. To Refit, Clean and warm area. Using a suitable bearing drift, drive #6202FF or SS bearing into place, taking note not to forget to refit the bearing/axle spacer. K) Reverse "A" thru "F". Don't forget to Safety Wire! 5) Rear. A) Place machine on cycle stand, rear only raised. B) Cut-off and remove all safety wire. C) Remove drive chain master-link, lay chain out of way. D) Remove rear brake rod/cable adjuster. E) Undo rear axle nuts half-way. F) Remove rear wheel. G) Repeat #4"G" & "H". H) Reverse "A" thru "G". Don't forget the Safety Wire! 6) Sprocket & Carrier. A) Remove rear wheel, see #5A-F. B) Remove right axle nut & chain adjuster. C) Pull sprocket carrier off. D) Check condition of carrier bearing and rubber cushion. Replace or Service as needed. To remove bearing, remove oil seal and snap-ring, warm carrier, drift out bearing. To refit, clean and warm carrier, using suitable bearing drift, refit bearing. Pack with grease, refit oil seal. E) Check condition of sprocket bolts and lock nuts.Replace or Service as needed. To remove sprocket, undo six (6) 1/4" allenhead screws and remove sprocket. NOTE: After a number of sprocket changes, it is very wise to replace the Nylock 1/4" nuts located in the back side of the sprocket carrier. We fit/use 1/4”x28tpi nylocks with hardened allen screws. F) Refit rear wheel, Reverse #5A-G. G) Refit drive chain and master-link. To adjust chain, snug up axle nuts lightly. Using a tape measure, check distance from center of rear axle to backside of swingarm pin, it must be the same on both sides. Con't .... Chain slack should be approx 1/4" - 3/16" with rear shocks compressed. Tighten rear axle nut, taking care to re-check measurements from axle to swingarm pin. Repeat? H) Safety Wire as required. 7) Spokes. A) Check for loose and/or broken spokes. B) Remove wheel in question, repair as needed. NOTE: "Wheel Work" should ALWAYS be undertaken by Specialists. |

|

|

| Left: A broken rear axle while leading 350GP race at Firebird, AZ., in 1991 resulted in a DNF on the last lap... DON'T use the old "step" type axles, use only straight ones. Years later a bearing holder in the rear hub would sheer off. Check your hubs & axles regularly. |